What is necessary for ceramic digital printing

Whether you're just starting out or already have experience: our goal is to support you step by step – with personal guidance, technical clarity, and a real person by your side. We usually communicate in your native language – directly, clearly, and solution-oriented.

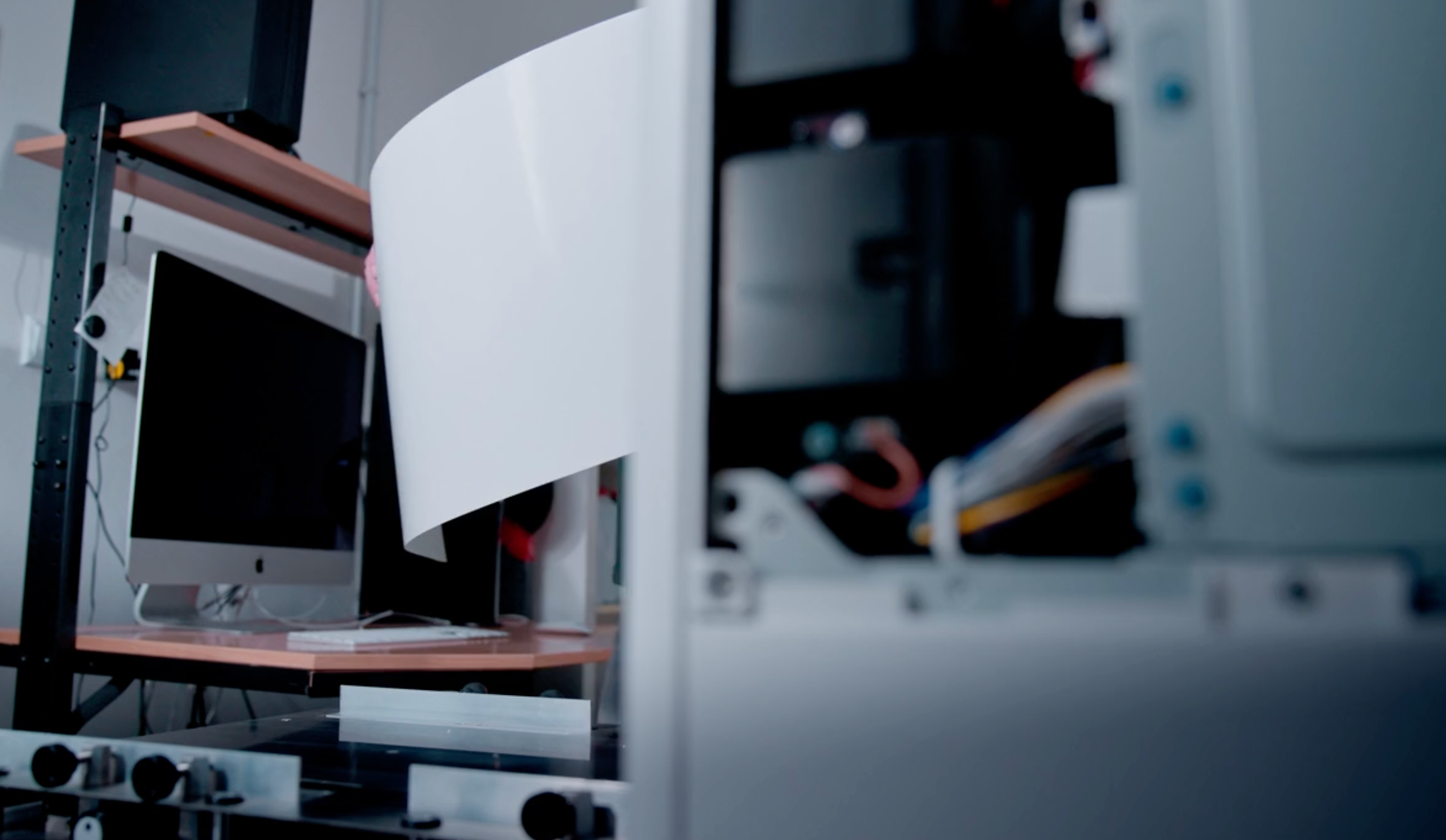

Computer & Software

We recommend using professional image editing software such as Adobe Photoshop® – ideally with Adobe® Print Tools for precise color control.

Modified laser printers

The patented printing system enables the production of high-resolution water-slide decals that can be reliably transferred onto ceramics, porcelain, glass, enameled metal, or earthenware.

Ceramic Toner & Developer by MZ

They contain inorganic pigments that are heat-resistant and fuse permanently with the glaze during the firing process.

44 / 5.000Printing and transfer papers

• Uncoated decal papers, which need to be coated after printing, or

• Pre-fabricated direct-print papers that are already coated with a lacquer layer and are ready to use immediately.

Examples include: – MZ CoverCal for inglaze applications – MZ PureCal for food-safe designs – MZ BasiCal for universal applications

Varnish & Lamination

kiln

Color systems for maximum expressiveness

One of the most challenging aspects in ceramic printing is achieving accurate reproduction of the color red. That’s why ceramictoner by MZ Toner Technologies offers several specially optimized color gamuts:

– MC Multi Color Professional: Maximum color variety & flexibility. Easy color correction for portraits – ideal for ultra-fast applications starting from 800 °C. From 950 °C, a glossy ceramic surface is achieved without additional flux. Maximum firing temperature: 1250 °C.

– Magenta Gamut: Ideal for delicate pastel tones and violet/purple shades.

– Red Gamut: Delivers vibrant, warm red tones and striking brightness – perfect for logos, brand colors, or decorative highlights.

All color systems are precisely matched to the modified printers and papers from MZ Toner Technologies, ensuring maximum color reliability in the final result.

Diversity in form and function

In addition to classic applications such as tableware decoration, souvenirs, wall and floor tiles, or plaques, digital ceramic printing is also used for large-format objects. These include backlit design panels for interior architecture or façade elements made of glass and ceramics that turn buildings into striking visual highlights.

Ceramic Refinement with Water-Slide Transfer Images

These decals, also known as water-slide transfers, are developed and manufactured by MZ Toner Technologies in Germany. They are known for their easy handling and long-lasting results: after printing, the decals are placed in water, which allows the printed layer to effortlessly detach from the backing paper. The design can then be flexibly positioned on ceramics, glass, or porcelain. Thanks to this technique, detailed and durable decorations are created for tableware, tiles, glassware, and much more – efficiently, precisely, and with brilliant color quality.

Sustainability meets economic efficiency

• Environmentally friendly • Odor-free and pleasant for employees • Space-saving – no screen storage or cleaning needed • Cost-reducing – no special ventilation required

This allows production environments to be designed with greater flexibility and efficiency – even in sensitive areas.

Focus on speed and flexibility

• Print-on-demand in real time • Top quality with up to 8 colors • Small and large production runs with maximum cost-efficiency • Format flexibility – ideal for the sanitaryware, construction, and porcelain industries

Ceramic digital printing with modified laser printers enables razor-sharp image reproduction at resolutions of 600 to 1,200 dpi – ideal for detailed designs such as portraits, illustrations, or logos.

The result: brilliant colors and stunning clarity, even on complex surfaces.

Unlike screen printing, the digital process does not require time-consuming image changes. New designs can be loaded at any time – with no setup time required.

This saves both time and costs, especially for small batches, personalized one-offs, or flexible series production.

Digital printing is carried out on special water-slide transfer paper, meaning the object to be decorated does not need to be present during printing.

The decals can be pre-produced, stored, or shipped worldwide and transferred to the substrate at a later time – ideal for decentralized production or on-demand projects.

After printing and transfer, the decoration is fired at temperatures between 580 and 1250 °C.The inorganic pigments used permanently fuse with the glaze or surface, ensuring an extremely durable, UV- and chemical-resistant decoration.